Introduction to PVC, an important component of the plastic family

Polyvinyl chloride (PVC) ranks as the world’s thirdlargest thermoplastic, with annual production exceeding 45 million tonnes and a market value approaching $80 billion. Its balance of strength, durability, low cost and ease of processing underpins extensive use across construction, electrical, medical and packaging sectors. PVC’s two main grades—rigid (uPVC) and flexible (PVC-P)—are complemented by specialty variants like CPVC, PVC-O and PVCM to meet evolving performance demands. Commercial manufacture relies primarily on suspension and emulsion polymerization, with some bulk processes. For global buyers, TDDglobal’s chemical industry B2B platform streamlines sourcing of PVC and related additives through certified suppliers, integrated logistics and real-time pricing feeds.

Global PVC production reached nearly 45 million tonnes in 2022, growing at a compound annual rate of about 4.8 percent ChemAnalyst.

Its annual consumption exceeds 48 million tonnes worldwide, reflecting steadily rising demand.

Market analysts estimate the PVC sector’s value at nearly $80.5 billion in 2023, poised to expand to over $98.6 billion by 2028.

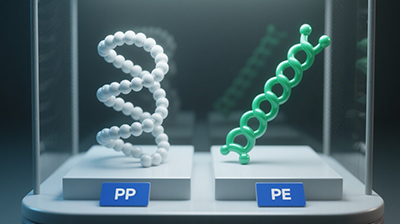

As the thirdmost produced thermoplastic after polyethylene and polypropylene, PVC accounts for a significant share of the global resin market.

PVC is a versatile thermoplastic polymer available as white powder or granules and exhibits densities between 1.1–1.45 g/cm³ depending on grade.

Rigid PVC (uPVC) offers high impact strength, weather resistance and a glass transition temperature around 70–80 °C, though heat distortion begins near 60 °C without stabilizers.

Flexible PVC achieves clarity and pliability through plasticizers that lower crystallinity, while retaining good chemical resistance and electrical insulation.

Specialty variants include CPVC (higher chlorine content for heat and chemical stability), PVC-O (bi-axially oriented for enhanced stiffness and fatigue resistance) and PVC-M (modified blends for improved toughness) Wikipedia.

In building and construction, PVC’s durability and costeffectiveness make it the material of choice for window profiles, siding, roofing, flooring and both potable and wastewater pipelines.

Electrical and telecommunications cables benefit from PVC’s excellent insulation and fireretardant properties, while its low cost drives use in flexible conduit and wiring jackets.

Healthcare relies on PVC for medical tubing, blood bags and disposable devices due to its clarity, sterilizability and biocompatibility.

Emerging applications span automotive interiors, packaging films, inflatable structures and 3Dprinted components, leveraging PVC’s tunable properties across grades.

Commercial PVC resin is produced mainly via suspension polymerization—by far the dominant method—alongside emulsion and, to a lesser extent, bulk (mass) polymerization.

The suspension process involves polymerization in aqueous solution, recovery of unreacted vinyl chloride monomer (VCM) and subsequent drying of PVC beads .

Emulsion polymerization yields finer particles in an autoclave environment using surfactants and watersoluble initiators, catering to specialized compounding needs .

Bulk or mass polymerization, though less common, offers highpurity PVC for niche applications by polymerizing VCM without dispersing media.

As a leading chemical industry B2B platform, TDD-global connects buyers with certified chemical manufacturers, REACHcompliant suppliers and ISO-certified sources for reliable PVC resin and additives.

Its China Chemical B2B Marketplace feature grants direct access to major resin exporters and cross-border warehousing options, while integrated logistics solutions—end-to-end trade services and freight forwarding—ensure timely delivery.

Realtime pricing feeds for bulk materials, including Rutile Grade Titanium Dioxide and specialty plasticizers, empower procurement teams to secure competitive rates and maintain uninterrupted production.

By uniting a global chemical business network, TDD-global simplifies secure B2B transactions and streamlines the entire chemical supply chain from quotes to qualitycompliant delivery.